Protecting Life.

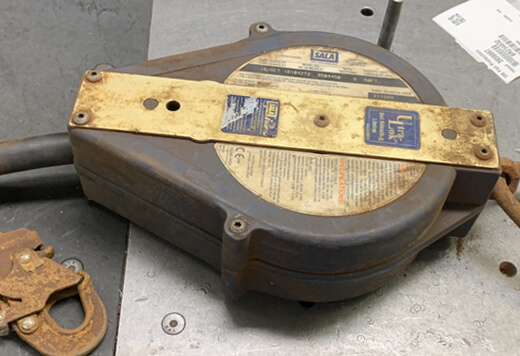

Sustaining Assets.

What to expect?

A turnkey solution

From initial design through to ongoing inspection, RIGCOM takes care of all your height safety needs including risk assessment, engineering, custom fabrication, installation, inspection, management and reporting, recertification and after sales service.

“Your support and professionalism on Snowy Hydro assets, and over a large number of different projects, is greatly appreciated. Your business genuinely assists us in performing our jobs more safely and efficiently. A great partnership if ever I have encountered one.”

Peter Patsalou, Contracts Manager, Snowy Hydro Limited.

Careers at RIGCOM

Click here for details of current job opportunities at RIGCOM.

TAILORED TO YOUR INDUSTRY

Request a proposal

Leave your details so that our estimating and design team can assess your project.

Receive a proposal and free consultation.